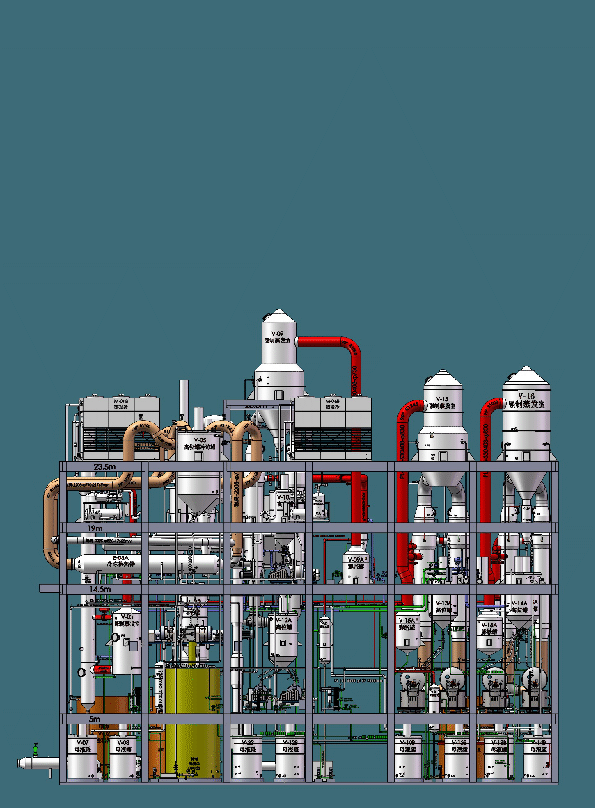

Energy-saving refrigeration technology

Main Advantages and Characteristics:

Anti-clogging: Ensures heat transfer temperature difference ≤3°C in liquid-liquid heat exchange to avoid crystal scaling.

Refrigerant Direct Cooling: Saves about 50% energy compared to ethylene glycol refrigeration via phase change heat transfer.

Patent Protection for Core Technologies:

4 invention patents for its refrigerant direct cooling forced freezing crystallization technology, as follows: Sodium Sulfate Purification System and Treatment Process (ZL202211275088.9);Resource Treatment System and Method for Battery Raffinate Liquid (ZL202210134032.5); Process for Preparing Lithium Carbonate from Lepidolite Roasting Leachate (ZL202311615547.8); Size Design Method and System for Continuous Freezing Crystallization Kettle (ZL202410698903.5)。

Utility Model Patents Portfolio:Forced Freezing Heat Exchanger (ZL202220233021.8); Wastewater Treatment System for Dinaphthol Containing Sodium Sulfate and Sodium Sulfite (ZL201922195699.2)。

Customer Cases:

1.Jiangxi Battery Enterprise's 28.5 m³/h sodium sulfate solution freezing crystallization system;

Energy Consumption per Ton of Treatment: Electricity 18 kW, circulating water 5.6 tons.

55% energy saving compared to traditional freezing.

2.Jining Pigment Enterprise's 21-ton/hour sodium sulfite solution freezing crystallization system

Energy Consumption per Ton of Treatment: Electricity 19.7 kW, circulating water 17 tons.

50% energy saving compared to traditional freezing.

3.Quannan Battery Enterprise's 20T/h lithium-containing sodium sulfate solution freezing system

Energy Consumption per Ton of Treatment: Electricity 15.7 kW, circulating water 11 tons.

40% energy saving compared to traditional freezing, with improved lithium recovery rate.

English

English