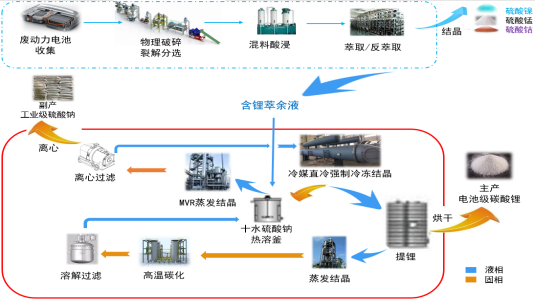

High-yield lithium extraction technology and equipment for waste power batteries, spodumene and lepidolite

main advantages and characteristics: high-yield lithium extraction technology and equipment

After lithium precipitation, the solution is frozen and then directly evaporated to obtain lithium carbonate, saving production cost by 7,000 RMB per ton of lithium carbonate.

For each ton of lithium carbonate, it can save 2.3 tons of sodium carbonate and 2.17 tons of concentrated sulfuric acid, and reduce the generation of 3.1 tons of sodium sulfate (calculated based on the industry average lithium loss rate of 0.05%, which reduces 7.5 kg of lithium carbonate entrainment and 5.4 tons of evaporation volume. In the traditional process, each ton of lithium carbonate produces 22.7 tons of Glauber's salt with a lithium entrainment loss of 60 kg).

Calculated based on sodium carbonate at 1,500 RMB/ton, lithium carbonate at 70 RMB/kg, concentrated sulfuric acid at 300 RMB/ton, and evaporation cost at 40 RMB/ton: The cost savings per ton of lithium carbonate are: 2.3×1,500 + 67.5×70 + 300×2.17 + 40×5.4 = 9,042 RMB. The additional power consumption for freezing per ton of lithium carbonate is 2,024 RMB, so the total cost reduction per ton is: 9,042 - 2,024 = 7,018 RMB.

Meanwhile, the production process is shortened, eliminating the operational risks of repeated acid-base adjustment. It enables continuous large-scale production without blockages or scaling!

All kinds of raw materials such as lithium spodumene/lithium mica/battery recycling are suitable for this technology!

Key Customers: CATL, EVE Energy, Geely Group, Dynanoboo, Tengyuan Cobalt Industry, Nandu Power, Natel Energy, Ruilong Technology, Xinlong Lithium Industry, Saikeweier, etc.

English

English